Red Jacket® series of submersible turbine pumps

The cornerstone of your fuelling infrastructure, the Red Jacket® series of submersible turbine pumps is the foundation model that sets the standard for high throughput, high reliability fuelling applications.

Request a Quote Brochure (PDF)

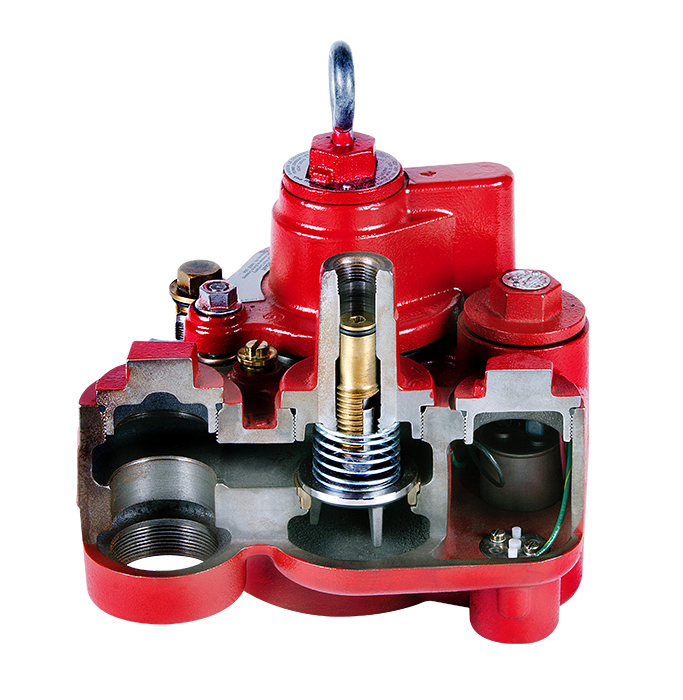

The Red Jacket® Submersible Pumping Systems

The Red Jacket® STP

Red Jacket STP is the most widely installed submersible fuel pump in the world. And that’s because Red Jacket continues to deliver the highest efficiency and fuel flow, together with the lowest power consumption, in the industry. Since 1878, Red Jacket has continued our tradition of building a high quality, reliable pump that is BUILT TO LAST.

Extensive range options

¾, 1½ or 2 HP versions 3-phase/50Hz to suit wide range of applications and site configurations.

Pressure technology

Less pipe work and fewer moving parts than equivalent suction system, without risk of vapour lock.

Consistent flowrate

Pump fuel efficiently over greater distances at higher temperatures and altitudes.

Integrated line leak

Mechanical or electronic line leak controlled by TLS monitoring system with automatic shutdown for maximum environmental protection.

Uniquely designed extractable

When removed, check valve, leak detector and siphon cartridge remain in manifold and do not require disconnection.

Hazard isolation

The electrical connection is automatically broken as the extractable is removed. This means that fuel in the manifold and non-isolated piping drains are sent safely back to the tank preventing spills and reducing service costs.

Vertical product discharge

Allows easier connection to horizontal pipe work using standard pipe fittings.

Twin siphon ports

Two siphon cartridge ports allow connection to multiple systems. Unique swivel design allows easier connection.

Lockable check valve

Easily relieve pressure and drain non-isolated product in the manifold and line safely into the tank for testing or maintenance.

Superior motor design

- Higher flow rates, lower power consumption, and increased safety and reliability.

- Up to 5% Increased Flow – Improved stator and receptacle housing design provides larger fuel paths.

- 8% Less Power Consumption – More efficient motor design results in 8% reduction in wattage.

- Better Quality – Red Jacket’s motor manufacturing yields improved quality, which means more station uptime than other STPs on the market.

- Universal Compatibility – Fewer parts to stock.

- Improved Reliability – Improved bearing design and upgraded insulation yield longer motor life.

- Increased Safety – Maximum temperature remains ~125 degrees cooler vs. competitive models. Enhanced connectors separation meets latest flameproof standards.

Advanced packer manifold design

- Fast installation, simple service and testing, and sets the standard for electrical and environmental safety:

- Built-in Isolated Contractor’s Box – Electrical connection housing is built into the manifold and is completely isolated from the fuel path.

- Easy to Install and Service – No adjustment required to fit yoke, assembly is quick.

- Increased Electrical Safety – Automatic electrical yoke disconnects upon removal of extractable bolts.

- Environmentally Friendly – Automatic breaking of extractible seal upon bolt removal ensures automatic fuel drain back into tank, protecting the environment from contamination and site owners from related liability.

- Innovative Check Valve Design – “Open” setting makes for easier line tests and servicing.

| Red Jacket 4” Submersible Turbine Pumps | ||||

| Horse Power | 0.75 | 1.5 | 1.5 x 4 | 2.0 |

| Performance Specifications | ||||

| Flow rate @ 0.7 Bar in petrol | 200 LPM | 300 LPM | 220 LPM | 330 LPM |

| Static pressure in petroleum | 2.4 Bar | 2.5 Bar | 2.8 Bar | 3.1 Bar |

| Installation Requirements | ||||

| Electrical supply | 3-phase, 50Hz, 380 – 415 Volts AC | |||

| Required NPSH (Net Positive Suction Head) | 100 mm above pump inlet | |||

| Certification | ||||

| ATEX approval | II 1/2 G EN15268 IIA T3 DEMKO 12 ATEX 1247797 X | |||

| Special conditions for safe use | See Manual 577014-049 for details of installation, operation and maintenance requirements | |||

| Field replacements for older STP models | ||||

| New Replacement UMPs are available for old 3-phase and Single phase models - please refer to the current Red Jacket EU Price List | ||||

The Red Jacket® AG STP

The cornerstone of your alternative fueling infrastructure, the Red Jacket® AG series of submersible turbine pumps are built on the foundation of The Red Jacket® model and is specially designed for resiliency in the harsh alternative fuel environment.

The Red Jacket® AG STP is compatible with Ethanol or Methanol concentrations up to 100% and MTBE, ETBE or TAME concentrations up to 20%, and is UL79A and UL79B certified for use with renewable biofuels.

| Red Jacket 4” Submersible Turbine Pumps | ||||

| Horse Power | 0.75 | 1.5 | 1.5 x 4 | 2.0 |

| Performance Specifications | ||||

| Flow rate @ 0.7 Bar in petrol | 200 LPM | 300 LPM | 220 LPM | 330 LPM |

| Static pressure in petroleum | 2.4 Bar | 2.5 Bar | 2.8 Bar | 3.1 Bar |

| Installation Requirements | ||||

| Electrical supply | 3-phase, 50Hz, 380 – 415 Volts AC | |||

| Required NPSH (Net Positive Suction Head) | 100 mm above pump inlet | |||

| Certification | ||||

| ATEX approval | II 1/2 G EN15268 IIA T3 DEMKO 12 ATEX 1247797 X | |||

| Special conditions for safe use | See Manual 577014-049 for details of installation, operation and maintenance requirements | |||

| Field replacements for older STP models | ||||

| New Replacement UMPs are available for old 3-phase and Single phase models - please refer to the current Red Jacket EU Price List | ||||

Advanced Design

Easy to install and service

Fixed speed technology cuts down installation costs and avoids electrical interference with your ATG, POS, Cameras, and Intercoms. Red Jacket Pumps also feature an integrated yoke and junction box, eliminating the need for external components and further streamlining the installation process.

Global Safety Certification

The Red Jacket portfolio of submersible turbine pumps contains a variety of solutions to comply with global standards and are recognized by all major regulatory bodies.

Advanced Controls

Flow Optimisation

Monitor demand at the site and stage on additional pumps to ensure optimal fuel flow at all demand conditions.

Connectivity

Connect to your TLS-450PLUS to activate tanks based on easily set fuel parameters in manifolded tanks.

Custom User Access

Manifold together two Red Jacket STPs at sites with high demand to ensure flow rates and the ability for pumps to back each other up.

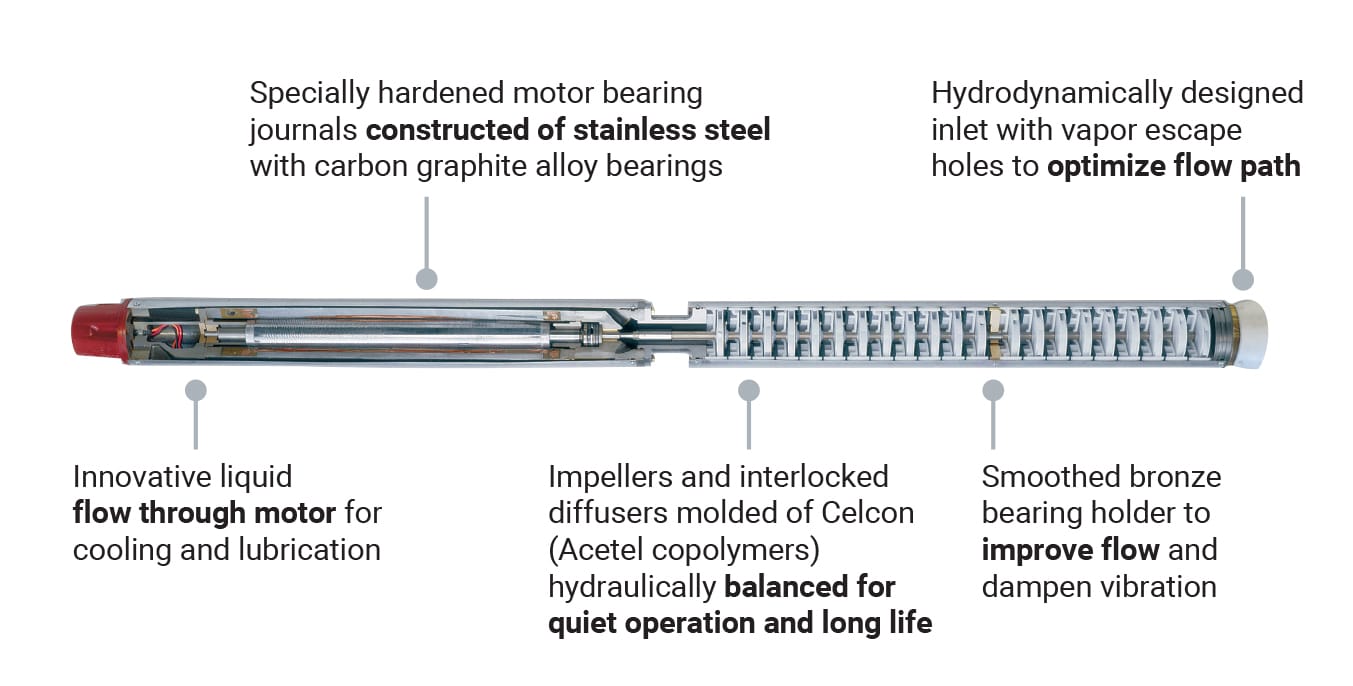

LPG Premier Range

The most effficient way to pump LPG

Maintain optimum flow rates quietly to enhance customer experience, pump LPG greater distances, gain flexibility in station design and eliminate vapour lock conditions.

Red Jacket Premier

- Entry level option for lower flowrate requirements.

- Flowrate 70 litres per minute at 7bar.

Red Jacket Premier MidFlow

- For LPG refuelling applications with low to intermediate flow requirements.

- Flowrate 100 litres per minute at 7bar.

Red Jacket Premier HiFlow

- For higher capacity installations such as commercial vehicle fuelling facilities and bottle filling plants.

- Flowrate 150 litres per minute at 7bar.

Specially hardened motor bearing journals constructed of stainless steel with carbon graphite alloy bearings

Hydrodynamically designed inlet with vapor escape holes to optimize flow path

Innovative liquid flow through motor for cooling and lubrication

Impellers and interlocked diffusers moulded of Celcon (Acetel copolymers) hydraulically balanced for quiet operation and long life

Smoothed bronze bearing holder to improve flow and dampen vibration

| Model | Premier | Premier MidFlow | Premier HiFlow | |

| Flow rate at 7 Barª | 70 litre/min | 100 litre/min | 150 litre/min | |

| Flow rate at maximum efficiency | 70 litre/min at 6.8 bar | 130 litre/min at 5.8 bar | 130 litre/min at 8.1 bar | |

| Flow rate at 4 Barª | 100 litre/min | 170 Litre/min | 190 litre/min | |

| Motor | Vac | 380-415 | 380-415 | 380-415 |

| Hz | 50 | 50 | 50 | |

| Hp | 3 | 3 | 5 | |

| KW | 2.2 | 2.2 | 3.7 | |

| Pump stages | 21 | 17 | 24 | |

| Unit length (mm) | 1506 | 1506 | 1896 | |

| Unit weight (kg) | 39 | 39 | 48 | |