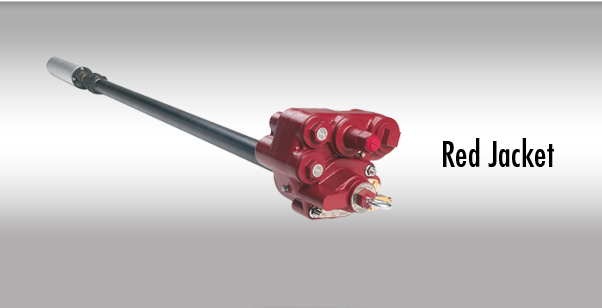

Red Jacket STP is the most widely installed submersible fuel pump in the world. And that’s because Red Jacket continues to deliver the highest efficiency and fuel flow, together with the lowest power consumption, in the industry. Since 1878, Red Jacket has continued our tradition of building a high quality, reliable pump that is BUILT TO LAST.

Superior motor design

- Higher flow rates, lower power consumption, and increased safety and reliability.

- Up to 5% Increased Flow – Improved stator and receptacle housing design provides larger fuel paths.

- 8% Less Power Consumption – More efficient motor design results in 8% reduction in wattage.

- Better Quality – Red Jacket’s motor manufacturing yields improved quality, which means more station uptime than other STPs on the market.

- Universal Compatibility – Fewer parts to stock.

- Improved Reliability – Improved bearing design and upgraded insulation yield longer motor life.

- Increased Safety – Maximum temperature remains ~125 degrees cooler vs. competitive models. Enhanced connectors separation meets latest flameproof standards.

Advanced packer manifold design

- Fast installation, simple service and testing, and sets the standard for electrical and environmental safety:

- Built-in Isolated Contractor’s Box – Electrical connection housing is built into the manifold and is completely isolated from the fuel path.

- Easy to Install and Service – No adjustment required to fit yoke, assembly is quick.

- Increased Electrical Safety – Automatic electrical yoke disconnects upon removal of extractable bolts.

- Environmentally Friendly – Automatic breaking of extractible seal upon bolt removal ensures automatic fuel drain back into tank, protecting the environment from contamination and site owners from related liability.

- Innovative Check Valve Design – “Open” setting makes for easier line tests and servicing.

| Red Jacket 4” Submersible Turbine Pumps | ||||

| Horse Power | 0.75 | 1.5 | 1.5 x 4 | 2.0 |

| Performance Specifications | ||||

| Flow rate @ 0.7 Bar in petrol | 200 LPM | 300 LPM | 220 LPM | 330 LPM |

| Static pressure in petroleum | 2.4 Bar | 2.5 Bar | 2.8 Bar | 3.1 Bar |

| Installation Requirements | ||||

| Electrical supply | 3-phase, 50Hz, 380 – 415 Volts AC | |||

| Required NPSH (Net Positive Suction Head) | 100 mm above pump inlet | |||

| Certification | ||||

| ATEX approval | II 1/2 G EN15268 IIA T3 DEMKO 12 ATEX 1247797 X | |||

| Special conditions for safe use | See Manual 577014-049 for details of installation, operation and maintenance requirements | |||

| Field replacements for older STP models | ||||

| New Replacement UMPs are available for old 3-phase and Single phase models - please refer to the current Red Jacket EU Price List | ||||